| |

SIZE |

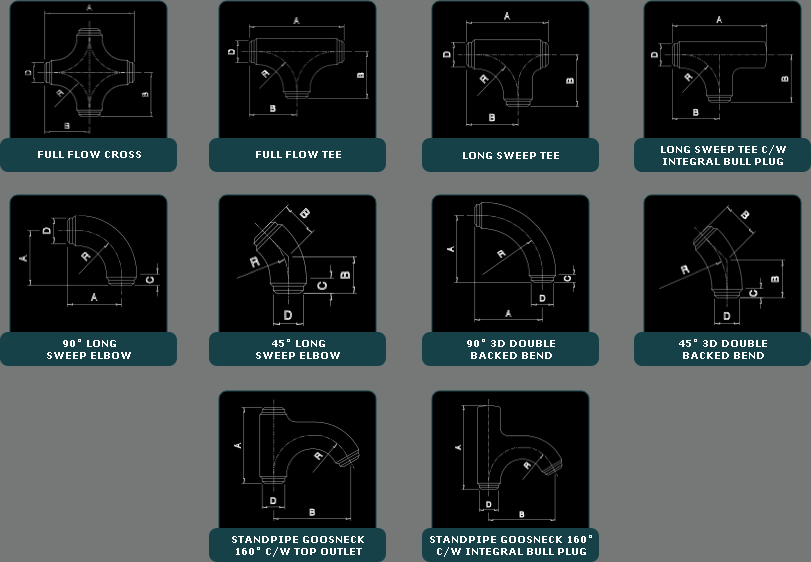

FULL FLOW CROSS |

APPROX

WEIGHT (Kg) |

|

| D |

A |

B |

R |

| 2” |

60.3 |

406 |

203 |

150 |

54 |

| 3” |

88.9 |

406 |

203 |

150 |

48 |

| 4” |

114.3 |

560 |

280 |

210 |

94 |

| 5” |

141.3 |

610 |

305 |

240 |

138 |

| |

6” |

168.3 |

762 |

381 |

305 |

208 |

|

|

|

| |

SIZE |

FULL FLOW TEE |

APPROX

WEIGHT (Kg) |

|

| D |

A |

B |

R |

| 2” |

60.3 |

406 |

203 |

150 |

39 |

| 3” |

88.9 |

406 |

203 |

150 |

33 |

| 4” |

114.3 |

560 |

280 |

210 |

63 |

| 5” |

141.3 |

610 |

305 |

240 |

90 |

| |

6” |

168.3 |

762 |

381 |

305 |

143 |

|

|

| |

|

|

| |

SIZE |

LONG SWEEP TEE |

APPROX

WEIGHT (Kg) |

|

| D |

A |

B |

R |

| 2” |

60.3 |

330 |

203 |

150 |

33 |

| 3” |

88.9 |

330 |

203 |

150 |

28 |

| 4” |

114.3 |

406 |

280 |

210 |

51 |

| 5” |

141.3 |

483 |

305 |

240 |

76 |

| |

6” |

168.3 |

686 |

381 |

305 |

132 |

|

|

|

| |

SIZE |

LONG SWEEP TEE C/W INTEGRAL BULL PLUG |

APPROX

WEIGHT (Kg) |

|

| D |

A |

B |

R |

| 2” |

60.3 |

406 |

203 |

150 |

44 |

| 3” |

88.9 |

406 |

203 |

150 |

37 |

| 4” |

114.3 |

560 |

280 |

210 |

71 |

| 5” |

141.3 |

610 |

305 |

240 |

100 |

| |

6” |

168.3 |

762 |

381 |

305 |

154 |

|

|

| |

|

|

| |

SIZE |

90° LONG SWEEP ELBOW |

APPROX

WEIGHT (Kg) |

|

| D |

A |

R |

C |

| 2” |

60.3 |

203 |

150 |

53 |

20 |

| 3” |

88.9 |

203 |

150 |

53 |

14 |

| 4” |

114.3 |

280 |

210 |

70 |

39 |

| 5” |

141.3 |

305 |

240 |

65 |

57 |

| |

6” |

168.3 |

381 |

305 |

76 |

105 |

|

|

|

| |

SIZE |

STANDPIPE GOOSENECK 160° C/W INTEGRAL BULL PLUG |

APPROX

WEIGHT (Kg) |

|

| D |

A |

B |

R |

| 2” |

60.3 |

406 |

310 |

150 |

48 |

| 3” |

88.9 |

406 |

310 |

150 |

51 |

| 4” |

114.3 |

560 |

431 |

210 |

97 |

| 5” |

141.3 |

610 |

487 |

240 |

142 |

| |

6” |

168.3 |

762 |

600 |

305 |

255 |

|

|

| |

|

|

| |

SIZE |

90° 3D DOUBLE BACKED BEND |

APPROX

WEIGHT (Kg) |

|

| D |

A |

R |

C |

| 2” |

60.3 |

178 |

152 |

26 |

8 |

| 3” |

88.9 |

305 |

229 |

76 |

29 |

| 4” |

114.3 |

356 |

305 |

51 |

52 |

| 5” |

141.3 |

432 |

381 |

51 |

87 |

| |

6” |

168.3 |

533 |

457 |

76 |

177 |

|

|

|

| |

SIZE |

45° 3D DOUBLE BACKED BEND |

APPROX

WEIGHT (Kg) |

|

| D |

B |

R |

C |

| 2” |

60.3 |

121 |

152 |

58 |

7 |

| 3” |

88.9 |

171 |

229 |

76 |

19 |

| 4” |

114.3 |

177 |

305 |

51 |

31 |

| 5” |

141.3 |

209 |

381 |

51 |

50 |

| |

6” |

168.3 |

265 |

457 |

76 |

89 |

|

|

| |

|

|

| |

SIZE |

STANDPIPE GOOSENECK 160° C/W TOP OUTLET |

APPROX

WEIGHT (Kg) |

|

| D |

A |

B |

R |

| 2” |

60.3 |

330 |

310 |

150 |

47 |

| 3” |

88.9 |

330 |

310 |

150 |

48 |

| 4” |

114.3 |

406 |

431 |

210 |

91 |

| 5” |

141.3 |

483 |

487 |

240 |

133 |

| |

6” |

168.3 |

686 |

600 |

305 |

238 |

|

|

|

| |

SIZE |

45° LONG SWEEP ELBOW |

APPROX

WEIGHT (Kg) |

|

| D |

B |

R |

C |

| 2” |

60.3 |

118 |

150 |

56 |

14 |

| 3” |

88.9 |

118 |

150 |

56 |

9 |

| 4” |

114.3 |

162 |

210 |

75 |

26 |

| 5” |

141.3 |

171 |

240 |

72 |

37 |

| |

6” |

168.3 |

203 |

305 |

76 |

57 |

|

|

| |

|

|

|

|

|