Products

Turnkey Manifold

|

|||||

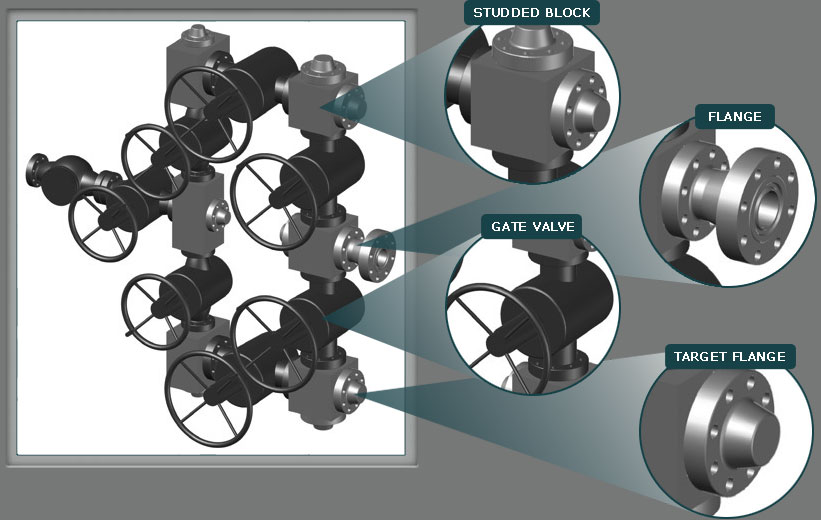

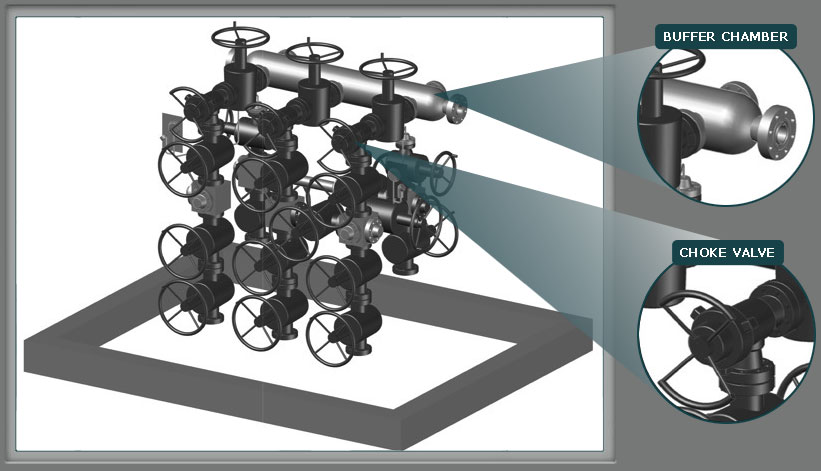

| By incorporating components such as Adjustable and Positive Chokes, Hydraulic Drilling Chokes, API Flanges, Hammer Lug Unions, API Studded Crossses and Tees, Adaptors, Spools, Blinds, Crossovers and Fittings, Choke Control Console, High Pressure Manifold Fittings, High Pressure Gate Valves (Manual and Hydraulic Gate Valves), High Pressure Plug Valves, Forged Crosses, Forged Tees, Forged Long Radius Elbows, Pressure Tested Assembly, Individually Pressure Tested Fittings and Gate Valves, Mud Vales, Drop Forged Manifold Fittings, Chokes, High Pressure Choke Valves, High Pressure Check Valves, Hammer Union Forged Tees and Elbows a depending on the application from our own stock availability, Oilquip can control the quality and programming of even very complex systems. | |||||

|

Oilquip is keen to work with clients to provide the right solution for individual projects. Where applicable or to meet client requirements and are supplied fully certified by independent third party authorities. |

|||||

|

Pressure & Temperature Ratings

| Max Working Pressure | 5,000 PSI | 7,500 PSi | 10,000 PSI | 15,000 PSI | 20,000 PSI |

| Test Pressure | 7,500 PSI | 11,250 PSI | 15,000 PSI | 22,500 PSI | 30,000 PSI |

| Production Spec Levels | 1, 2, 3 & 4 | 1, 2, 3 & 5 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 |

| Product Rating | 1 & 2 | 2 & 2 | 1 & 2 | 1 & 2 | 1 & 2 |

| API Temperature Rating | K (-60 Deg C) | K (-60 Deg C) | K (-60 Deg C) | K (-60 Deg C) | K (-60 Deg C) |

| To | To | To | To | To | |

| Y (+345 Deg C) | Y (+345 Deg C) | Y (+345 Deg C) | Y (+345 Deg C) | Y (+345 Deg C) |

Material Requirements

| Material Class | Body, Bonnet, End and outlet Connections | Pressure Controlling Parts |

| AA - General Service | Carbon or Low Alloy Steel | Carbon or Low Alloy Steel |

| BB - General Service | Carbon or Low Alloy Steel | Stainless Steel |

| DD - Sour Service** | Carbon or Low Alloy Steel* | Carbon or Low Alloy Steel* |

| EE - Sour Service** | Carbon or Low Alloy Steel* | Stainless Steel* |

*In accordance with NACE MR-01-75

**As defined in NACE MR-01-75

| Mud Standpipe Manifold |

.jpg) |

| Choke & Kill Manifold |

|

| Choke & Kill Manifold |

|